- The unique technology of manufacturing the mold walls

- Thermal design of molds

- Optimization of the cooling system of molds

- Types of mold damages and preventive measures

- Structural analysis of molds

- Increase of lifeability of molds

- Restoring the mold walls

- After-sales service of molds

- Design and analysis

MP Industries is exclusive partner of Mishima Mashprom joint venture.

Mishima company was founded in 1916 in Japan. Focusing on products with high added value it constantly creates and developes new technologies. As a result, the company has the highest level used technologies. Mishima company created a system that is ready to respond to new business needs, with its highest technical expertise and comprehensive technical solutions.

Mishima products with its unique features are known worlds over. Today their technologies are available in Europe through Russian-Japanese joint venture "Mishima-Mashprom".

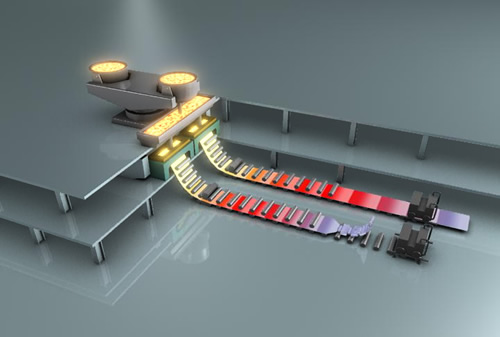

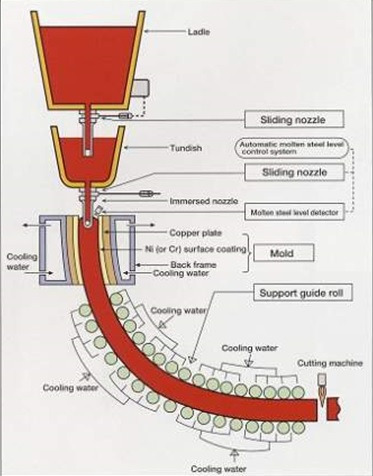

In April 2013 Mishima Kosan (Japan) and Mashprom (Russia) founded a joint venture to produce casting molds for continous-casting mashines (CCM) using Mishima Kosan technology. Production facilities are based in Russia (Nizhny Tagil). The results of pilot tests of casting molds for slab casters at one of the largest metallurgical plants EVRAZ NTMK surpassed all expectations. Indicated lifeability is one of the highest in the world and has no analogues in Russia and Europe. Indicators for resistance to mold wall with thermal spraying exceeds resistance up to 8 times than the resistance of the walls of casting molds currently used in Russia and Europe. Innovative technology for coating walls of caster molds became available to Russian and European companies and steel industry will improve the efficiency of production of metallurgical plants. Russian-Japanese joint venture "Mishima-Mashprom" offers an effective technology to prolong lifeability of molds coating and improve the quality of cast sections.

Continuous casting molds - main activities

- Surface treatment ofthe continuous castingmoldwithNi coating, Co-Ni coating and Ni-Crthermal spray.

- Identifying of problematic issuesand suggestions for improvingofthe continuous castingmolds.

- Operation and maintenance ofcompletecontinuous castingmolds.

- Production of various typesof continuous castingmolds.

- Development ofcontinuous castingmolds and equipment forthermal spraycoatings.